ISO 9001 Certification

Home » ISO 9001 Certification

ISO 9001 Certification

🕒 Get ISO 9001 Certified in 30 Days*

🚀 Boost Your Business Credibility & Win More Contracts

- Increase customer confidence and satisfaction

- Access new markets and business opportunities

- Reduce costs through improved processes

- Expert guidance from certified professionals

- 100% guarantee — we don’t get paid until you’re certified

🎁 Limited Time: Get a Free 2-Hour ISO 9001 Training & Awareness Session with Certificates — for a Group of 5!

Benefits of ISO 9001 QMS certification

📈 Boost Business Image

Boost your brand reputation with ISO 9001 — showing proven ability to deliver quality products and services.

🤝 Meet Customer Needs

Fulfil customer requirements and expectations, building trust and long-term relationships.

🔄 Process Integration

Unify management systems for smoother operations and better resource utilization.

📊 Data-Driven Decisions

Make informed, evidence-based decisions that enhance efficiency and reduce risks.

🚀 Continuous Improvement

Encourage teams to improve processes, save time, and cut costs consistently.

👩💼 Workforce Involvement

Engage and motivate your workforce for better performance and sustainable growth.

Applicability of ISO 9001:2015 – Industry Wise Benefits

| Industry | Benefits of ISO 9001 Certification |

|---|---|

| Manufacturing | ISO 9001 Certification in manufacturing ensures that an organization consistently meet regulatory requirements, improve product quality and efficiency, and meet customer satisfaction. |

| Construction | ISO 9001 Certification in construction ensures quality in construction materials, manage complex projects, meet regulations, and strengthen risk management. |

| Healthcare | ISO 9001 Certification in healthcare improve patient care, ensures compliance with healthcare requirements, and ensures patient satisfaction. |

| IT and Software | ISO 9001 Certification in IT and Software ensures quality of service delivery, reliable services, and improves software development. |

| Pharmaceuticals | ISO 9001 Certification in Pharmaceuticals ensures the compliance of an organization with regulatory requirements and product quality. |

| Telecommunications | ISO 9001 Certification in telecommunications ensures the consistent high-quality services, and customer satisfaction along with strong management protocols. |

| Logistics and Transportation | ISO 9001 Certification in Logistics and Transportation assures safe and efficient service delivery, strengthen supplier chain control, and ensures customer satisfaction. |

| Oil and Gas / Energy | ISO 9001 Certification in Oil and Gas / Energy ensures compliance with regulatory standards, and manage complex operations. |

| Automotive | ISO 9001 Certification in Automotive ensures that the organization meets global automotive quality standards. Along with this, it also assures that an organization has strong defect tracking and mitigating system. |

| Public Sector / Government | ISO 9001 Certification in Public Sector / Government ensures the citizen satisfaction, transparency, and standardization of service delivery. |

| Finance and Insurance | ISO 9001 Certification in Finance and Insurance ensures compliance with regulatory requirements, improvement in customer services, assures better handling of customer’s issues, and assures strong management of internal controls. |

SIS Certifications is accredited by IAS for ISO 9001Certifications. IAS- International accreditation services is an US based accreditation board which is a full member of IAF.

ISO 9001- Quality management system brings the concept of Managing the quality of their processes ensuring that the products and services are as per the specifications laid down by the customer and reaches them on time. The framework to make this true, ISO 9001 standards plays a vital role in bringing their organisation’s management system in place and according to the industrial needs leading to an extra edge for the competition.

📑 Table of Contents

- Benefits of ISO 9001 QMS Certification

- Applicability of ISO 9001:2015 – Industry Wise Benefits

- Apply for ISO 9001 Certification

- What is ISO 9001 QMS?

- Importance of ISO 9001 QMS Certification

- Major Aspects of ISO 9001 in Business

- Principles of ISO 9001 Certification

- Basic Steps for ISO 9001 Certification

- Is ISO 9001 Mandatory?

- Requirements of ISO 9001

- Cost of ISO 9001 Certification

- PDCA Cycle

- ISO 9001 FAQs

ISO 9001 is one of the most widely recognized standard for Quality Management System (QMS). It was published by the International Organization for Standardization (ISO) in 1987 and last upgraded in the year 2015. It provides a framework for organizations to consistently meet regulatory requirements, achieve operational excellence, deliver high-quality products and services, and enhance customer satisfaction. To obtain a certification, an organization must go through an audit conducted by an independent certification body.

In a certification body, resources play a vital role in meeting the expectation of customers, thus, it is essential to be audited by that body which understands the industry, such as SIS Certifications. It is a leading certification body (CB), which is recognized and accredited by renowned accreditation bodies such as IAS and UAF. The CB is equipped with the resources required to audit an organization’s management system.

SIS Certifications has more than 500 auditors and technical experts in more than 30 industries over 50 countries. The CB performs audit of multiple standards. SIS has auditor experts for all standards. Moreover, it offers hybrid audits where one auditor will be at the auditing site and others are using IC Tools. In addition to this, the CB is equipped with multilingual auditors, who understand and speak native as well as English language.

What is an ISO 9001 QMS Quality Management System?

ISO 9001- Quality management system brings the concept of Managing the quality of their processes ensuring that the products and services are as per the specifications laid down by the customer and reaches them on time. The framework to make this true, ISO 9001 standards plays a vital role in bringing their organisation’s management system in place and according to the industrial needs leading to an extra edge for the competition.

ISO 9001 certification is a quality management standard Certification that demonstrates the organization’s ability to provide products and services that meet customer and legal requirements within the organization.

ISO 9001 standards provide management tools and techniques to improve customer satisfaction and assist organizations in increasing efficiency. Quality management functions to achieve Quality Assurance and Quality Control.

Quality Assurance aims to design processes to produce products and services of appropriate quality and focuses on every aspect of the system, including suppliers and customers.

Quality Control focuses on operations related to producing the product or services and intends to eliminate factors that might cause undesired outputs.

Importance of an ISO 9001 QMS Certification

Quality Management System is a universal standard for Quality Management System and one of the most used ISO standards.

Over 1.4 million certificates have been issued in over 250 countries. (As per survey done by IAF for the year 2024)

85% of the certified organizations report benefits, such as higher demand for products and services, increased market share, and improved business operation.

ISO 9001 certification is the only standard in the ISO 9000 family of standards that requires certification. An entire organization seeks Certification, but the scope of the QMS can be accommodated to improve performance at a particular facility or department.

ISO 9001 Quality Management System and its All Major Aspect in a Business

Quality management is a key to success when we talk about business growth and its performance. That promotes client relations and plays a role in the well-being of business. To ensure the success of a business the quality of products and services will be maintained at all levels. This includes the planning, decision, and quality of procedure.

Quality is not only about ensuring the final product but also includes the process and the efforts behind the result.

Higher profitability is a crucial part of great quality. Higher quality promotes higher profits. And for this, it requires a high investment in a market. Minor failures in a company translate into the company’s manufacturing and service costs. Earning from this prevented the company’s expenditure and increased the market share and sales.

Efficient management grows the business makes it more sustainable and promotes productivity. This will help to make the changes with the competitor’s business. and promotes customer satisfaction.

Customers expect the standard of product from the company they purchase, without the quality the customer will deny purchasing from you because nowadays customers keep quality over quantity and don’t waste their hard-earned money on things that aren’t worth the same. Keep quality a priority that is maintained in each and every substance in a company and enhances customer peace of mind.

Higher standards of a product attract the customer to purchase back, and for this, the crucial part is to make essential changes, improve the quality, and update the product as the time and affordable, this has resulted in customer loyalty and customer coming back to you for other products.

The Principles of ISO 9001 QMS Certification

The ISO 9001 Certification places the concept of process management at the heart of the standard. It consists of eight core quality management principles that act as a common foundation for all standards relating to quality management.

Principles of ISO 9001:-

- Customer focus – It evaluates the organization’s objectives and initiatives to meet customers’ needs and requirements. The principle focuses on product performance and customer service.

- Leadership – This principle aims to establish a quality-minded culture. The top-level management plays a crucial role in establishing and maintaining work environments that engage people and achieve quality objectives.

- Engagement of People – It is one of the essential principles of ISO 9001 certification and focuses on making employees more competent, dependable, empowered, and better. It helps in the personal and professional development of the employees by establishing effective communication within the organization.

- Process Approach – It focuses on linking all the business processes in a single system and helps in achieving more predictable and consistent outcomes. It helps an organization focus on operations that need improvement.

- System Approach to Management – The process approach is a part of the system approach. It focuses on developing a cohesive system and improving individual performance by understanding, analysing, and managing interrelated business processes.

- Continual Improvement – Improving business operations is an ongoing process. It requires an organization to identify potential risks and opportunities and formulate strategies to eliminate risks and reap opportunities.

- Evidence-based Decision Making – It follows an evidence-based approach to the decision-making process. It evaluates all the data and implements appropriate tools and methods. The importance is given to understanding the cause-and-effect relationships and potential unintended consequences.

- Relationship Management – Establishing good relations with relevant partners, business associates, vendors, stakeholders, and investors is significant for an organization to ensure the continuity of the supply chain. Sustained success is more likely to be achieved when the organization manages relationships with all of its interested parties to optimize their impact on its performance.

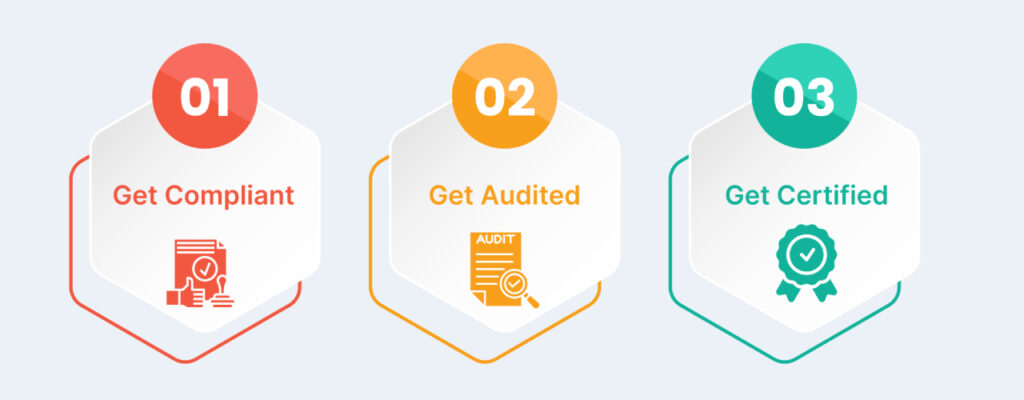

Basic steps for ISO 9001 Quality Management System Certification

ISO 9001 certification is an internationally accredited standard for Quality Management Systems. It requires an organization to establish effective quality management, and here is a checklist of 12 key steps that will guide you to achieve ISO 9001:

- Leadership

- Perform a Gap Analysis

- Defining the scope

- Implementation of Quality Management and Creating Quality Management System Manual

- Establishing effective communication within the organization

- Creation of an audit plan

- Determining and assigning roles and responsibilities

- Evaluating the Quality Management System and taking the actions

- Conduction of an internal audit

- Apply for stage-I audit

- External audit

- Successfully completing the Certification process

Along with the checklist there is a mandatory documentation list of ISO 9001 that need to be prepared to achieve ISO 9001 Certification.

Is ISO 9001 Certification mandatory or a legal requirement?

Since ISO 9001 certification is proof of your commitment to the quality of your products or services, it becomes a priority for your clients to do business with you. Also, you may find those suppliers trustworthy who are certified with ISO 9001. Thus, ISO 9001 certification is not a mandatory requirement, but it sure is a preferable one. In addition to that, ISO 9001 is also not a legal requirement. In fact, there are many standards, based on ISO 9001, for the implementation of Quality Management systems.

Organizations of any size or sector of operation can apply for ISO 9001 certification. The cost of obtaining this certificate varies from organization to organization, based upon the strength of their workforce, the complexity of their processes, and many other factors. Implementing a QMS on the basis of ISO 9001 may seem like a difficult task, but with proper guidance, it becomes easier, in addition, ISO 9001 certification might seem challenging to many, but with an experienced certification body, like SIS Certifications, the process of certification can be made hassle-free.

Requirements of ISO 9001 Certification

The structure of ISO 9001 consists of 10 sections, out of which the first three are introductory in nature, whereas the last seven specify the requirements of QMS, against which ISO 9001 certification is performed.

Clause 4: Context of the organization – This section deals with understanding the uniqueness of your organization and customizing ISO 9001 in order to implement a QMS that is most suitable for you.

Clause 5: Leadership – It underlines the importance of top management in the implementation of QMS by proper risk assessment, planning actions, and assigning roles and responsibilities to the relevant staff.

Clause 6: Planning – through analysis of the risks and opportunities, the top management is expected to design a plan that enlists the quality objectives for your organization.

Clause 7: Support – It points out all the resources, such as human resources, infrastructure, and others that are required for an effective QMS. This section also deals with the requirements around competence, awareness, communication, and controlling documented information.

Clause 8: Operation – this section deals with the execution part of the planning for QMS. It includes product requirements review, keeping a check on external providers, reviewing the product before release, and so on.

Clause 9: Performance evaluation – This section deals with the ways by which you can ensure the effective functioning of your QMS. It involves regular management reviews, monitoring and measurement techniques, etc.

Clause 10: Improvement – this section ensures that your QMS is upgraded and able to meet the current market requirements. It involves regular reviews to identify gaps and performing corrective actions to close those gaps for continual improvement.

Cost of ISO 9001 Certification

The cost of ISO 9001 Certification varies from one organization to another. ISO 9001 standards apply to any industry, large and small, irrespective of nature and location.

The cost of ISO 9001 certification depends on the certification body you choose. It also depends on many factors, such as:-

– Size of your organization.

– Number of employees in the organization.

– The number of branches your organization has and many more.

PDCA Cycle

- Plan – to think that what do we need to achieve in our organization

- Do – to execute a planned action which will help us achieve the required objective

- Check – monitor against the standards) (policies, objectives, requirements)

- Action – finally implementing what has been rechecked.

ISO 9001 Frequently Asked Questions (FAQs)

Answer: The latest version of ISO 9001 Certification is ISO 9001:2015, published in September 2015.

It focuses on enhancing customer and stakeholder satisfaction through effective application of processes.

Any organization—regardless of type, size, products, or services—can apply for it.

Answer : ISO 9001 Certification is a globally recognized standard for Quality Management Systems (QMS) which basically aims to cut costs and optimize all the processes operating in your organization and helps your organization to meet all the requirements of the customers and other stakeholders.

Answer:

Steps to apply for ISO 9001:2015 Certification:

Choose an internationally accredited certification body (e.g., SIS Certifications).

Submit an application form defining rights & obligations.

Auditor reviews documentation and identifies gaps.

Prepare action plan to close those gaps.

Undergo Stage I audit → review implementation.

Undergo Stage II audit → final certification audit.

Auditor submits report → Registrar issues ISO 9001:2015 certificate.

Answer:

ISO 9001 helps organizations:

Reduce operational costs

Increase profitability

Gain new customers

Retain customers long-term

It brings strong quality control, credibility, and market competitiveness.

Answer:

After certification, you must maintain your Quality Management System by:

Undergoing annual surveillance audits for 3 years

Ensuring continuous improvement and compliance

After 3 years, a recertification audit is required.

Answer:

ISO 9001 certificate is valid for three years.

Surveillance audits are conducted once every year during this period to ensure standards are maintained.

Answer:

The cost of ISO 9001 certification depends on:

Number of employees

Number of branches

Processes and operational complexity

Accredited certifying bodies quote prices based on system evaluation.

Answer:

Basic steps to get ISO 9001 certified:

Prepare all company information systematically

Document all business processes

Implement documented processes

Conduct internal audits

Undergo external certification audit

Once approved, your organization receives ISO 9001 certification.

CERTIFICATION PROCESS

Ready to Get ISO Certified?

Join 500+ Global Companies that have Successfully Achieved ISO Certification with Us.

Missing Something?

We’re here to help you find exactly what you need—just let us know, and we’ll guide you in the right direction.